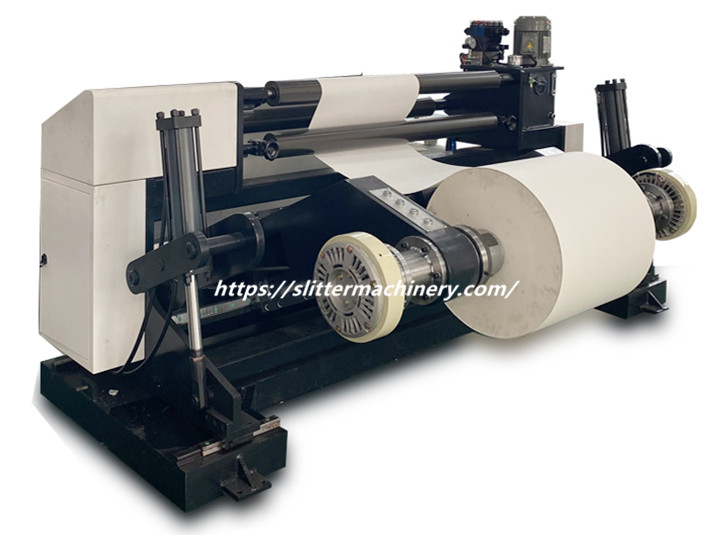

Slitter Rewinder for PAPER

It slits master roll into any desired width rolls

Normally, the original paper rolls from the paper mill are very big in size that we can not use them directly. Then the paper slitter rewinder is necessary to convert the large master rolls to needed size rolls.

Hochint specially designed the most suitable model–the HFQA, HFQL, HFQD, and other models to fit the needs of our clients who want to get rolls of the correct width and diameter.

Our slitter rewinders are designed for a variety of paper, ranging from 20g-500g, as following:

HFQA Series

| Model | HFQA-1300W | HFQA-1600W | HFQA-1800W | HFQA-2000W |

| Max. web width(mm) | 1300 | 1600 | 1800 | 2000 |

| Max. unwind diameter(mm) | Φ1400 | |||

| Unwind stand | Shaft-less auto loading & floating type | |||

| Unwind tension control | Magnetic powder brake with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) and 152mm(6”) step chuck | |||

| Web guiding system | Ultrasonic sensor | |||

| Slitting techniques | Rotary shear knife and Razor blade cutting in air | |||

| Trim disposal | Trim suction fan 2.2kw | |||

| Max. rewinding diameter(mm) | Φ1000(Φ1200 can be customized) | |||

| Rewinding tension control | Two rewinding servo motors with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) | |||

| Min. rewinding web width(mm) | 30 | 40 | 60 | 60 |

| Mechanical speed(m/min) | ≤400 | |||

| Cutting thickness | For paper:30-300g, For film: 30-300μm (according to the materials) | |||

| Cutting accuracy(mm) | ±0.15 | |||

| Main Motor Power(kw) | 7.5 | 7.5 | 11 | 11 |

| Rewind motor(kw) | 7.5*2 | 7.5*2 | 11*2 | 11*2 |

| Total power(kw) | 27 | 27 | 37 | 37 |

| Power supply | 380V 50HZ 3phases(other voltage can be customized) | |||

| Air supply | 0.6-0.8 Mpa, 0.8m3/Min | |||

| Net weight(kg) | 4500 | 5200 | 5800 | 6000 |

| Overall Dimension(mm) | 3700*3100*2100 | 3700*3400*2100 | 3700*3600*2100 | 3700*3800*2100 |

Features:

1. Three individual servo motors’ synchronous control provides accurate web tension which is calculated by PLC.

2. Siemens PLC control system with touch screen brings much convenience for the operator, it has multi-functions, like meter reached auto stop, tension auto control, and so on.

3. Shaftless unwind with hydraulic auto loading for heavy jumbo rolls and web guiding system to detect the web position.

4. Automatic rolls unloading structure for rewinding shafts: mechanical arm moving on the linear guide rail to unload the shaft.

5. Be equipped with rotary shear slitting knives and a high-power trim edge suction fan.

Standard configuration:

Unwinding system

- shaft-less unwinder, 3” and 6” use in common.

- Hydraulic lifter for heavy jumbo roll, Max diameter 1400mm and Max weight 2t.

- The left and right arms are controlled by hydraulic and can be moved separately.

- Tension control by magnetic powder brake

- Web-guiding system: an ultrasonic sensor to detect the web position

Transmission and driven system

- Main servo motor with frequency converter.

- Synchronous belt transmission.

- Pneumatic nip rubber roller.

Slitting section

- Circular knives 10 pcs

- Trim disposal: 3kw trim suction fan

Rewinding section

- Servo motor 2pcs for rewinding.

- Auto unloading system(Click here to see video): mechanical arm moving on the linear guide rail to unload the shaft with finished rolls

- 3-inch air shafts*2, the Max. Diameter is Φ1000

- Pneumatic lay-on roller guarantees full contact between lay-on roller and slit roll

Electric section

- LCD colorful touch-screen and PLC (Siemens).

- Unwinding tension control and rewinding tension adjustment.

- Speed adjustment function.

HFQL Series

| Model | HFQL-1300 | HFQL-1600 | HFQL-1800 | HFQL-2000 | HFQL-2600 | HFQL-3000 |

| Max. web width(mm) | 1300 | 1600 | 1800 | 2000 | 2600 | 3000 |

| Max. unwind Dia(mm) | Φ1800 | |||||

| Unwinding stand | Heavy duty shaft-less auto loading & floating type | |||||

| Unwinding tension control | Pneumatic brake with PLC control | |||||

| Inner core diameter(mm) | 76mm(3”) & 152mm(6”) step chuck | |||||

| Web guiding system | Ultrasonic sensor | |||||

| Slitting techniques | Rotary shear knife | |||||

| Trim disposal | Trim suction fan 5.5kw | |||||

| Max. rewind Dia(mm) | Φ1500 | |||||

| Rewinding tension control | Two rewinding servo motors | |||||

| Inner core diameter(mm) | 76mm(3”) | |||||

| Min.slitting width(mm) | 50 | 50 | 50 | 60 | 80 | 100 |

| Mechanical speed(m/min) | ≤500 | |||||

| Cutting thickness | For paper:50-450g (according to the materials) | |||||

| Cutting accuracy(mm) | ±0.15 | |||||

| Main motor(kw) | 18.5 | 18.5 | 18.5 | 18.5 | 22 | 22 |

| Rewind motor(kw) | 15*2 | 15*2 | 15*2 | 15*2 | 18.5*2 | 18.5*2 |

| Total power(kw) | 55 | 55 | 57 | 58 | 65 | 67 |

| Power supply | 380V 50HZ 3phases(other voltage can be customized) | |||||

| Air supply | 0.6-0.8 Mpa, 0.8m3/Min | |||||

| Weight(kg) | 13000 | 14500 | 15000 | 16000 | 20000 | 22000 |

| Overall Dimension(mm) | 8100*4400*2300 | 8100*4600*2300 | 8100*4800*2300 | 8100*5000*2300 | 8100*5600*2300 | 8100*6000*2300 |

Features:

1. Three individual servo motors with gear reducer synchronous control provides accurate web tension which is calculated by PLC.

2. Siemens PLC control system with touch screen brings much convenience for the operator, it has multi-functions, like meter reached auto stop, tension auto control, and so on.

3. Heavy-duty shaftless unwind with hydraulic auto loading for heavy jumbo rolls and web guiding system to detect the web position.

4. Automatic rolls unloading structure: hydraulic control to unload the shaft with heavy finished rolls.

5. Be equipped with durable SKD rotary shear slitting knives and a high-power trim edge suction fan.

6. Motor control web auto handling from unwind to traction roller can largely improve the efficiency of the operator.

Standard configuration:

Heavy-duty unwind stand

| 1. Floating type shaft-less unwind stand, 3”and 6” step chuck.

2. Hydraulic lifter for heavy jumbo roll, Max diameter 1800mm and Max weight 3600kg. 3. Left and right arm is controlled by hydraulic, and can be moved separately. 4. Web adjustment roller ensures the web tension balance from left to right.. 5. Tension is calculated by PLC and controlled by Italy RE pneumatic brake automatically. 6. Web-guiding system: ultrasonic sensor(Pausource) to detect the web position. 7. Constant closed-loop tension control system(optional): the tension is sensed by load cell sensor and compared to the set tension. |

Traction section

| 1. Web dancer roller for long path tension control

2. Motor control web auto handling from unwind to traction roller. 3. Banana roller to spread the web. 4. Servo motor is connected to the double traction rubber rollers. 5. Pneumatic nip rubber roller, the pressure of nip can be adjusted: providing perfect tension isolation. |

Slitting section

| 1. Rotary shear knives(SKD materials) 10 sets.

2. Cantilever upper knife shaft. 3. Upper knife up/down adjustment and left/right fine-adjustment are controlled pneumatically. 3. Pneumatic bottom knife shaft is convenient to unload or load the bottom rotary knives. 4. Trim disposal: 3 kw trim suction fan. |

Rewinding section

| 1. The left and right rewind structure, 2 pcs 3” strengthened airshaft center winding with shaft support, the Max. rewind diameter 1500mm.

2. Pneumatic clamp for rewind shaft. 3. Servo motor(2 sets) drive system with gear reducer provides the accurate winding tension control. 4. Automatic rolls unloading structure: hydraulic control to unload the shaft with heavy finished rolls. 5. Pneumatic rewind shaft laying on big metal cylinder guarantees full contact between big metal roller and slit roll, the lay-on pressure can be adjusted. |

PLC and touch screen

| 1. Colorful 10” touch-screen and PLC (Siemens).

2. Chinese, English and Russian language(optional) on touch screen 3. Automatic tension& diameter calculate and control: Set taper and initial tension on touch screen for your materials, PLC will detect current tension and current diameter automatically and accurately. 4. Meter reached auto alarm and stop function. 5. Unwind Set diameter reached auto alarm and stop function. 6. One button auto speed up function: Press one button, machine will speed up to your set speed smoothly and automatically. 7. Rewind shaft forward and backward function. 8. Problem diagnosis function on touch screen, if any problems occur, you can check I/O page to find it. |

HFQD Series

| Model | HFQD-1300 | HFQD-1600 | HFQD-1800 | HFQD-2000 |

| Max. web width(mm) | 1300 | 1600 | 1800 | 2000 |

| Max. unwinding diameter(mm) | Φ1800 | |||

| Unwinding stand | Shaft-less auto loading & floating type | |||

| Unwinding tension control | Two motors with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) and 152mm(6”) step chuck | |||

| Web guiding system | Ultrasonic sensor | |||

| Slitting techniques | Pneumatic automatic rotary shear knife(standard rotary shear knife is optional) | |||

| Trim disposal | Trim suction fan 3kw | |||

| Max. rewinding diameter(mm) | Φ1400 | |||

| Rewinding tension control | Motors with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) | |||

| Min. slitting width(mm) | 200 | |||

| Speed(m/min) | ≤600 | |||

| Cutting thickness | For paper:50-500g (according to the materials) | |||

| Unwind motor(kw) | 15*2 | 18.5*2 | 18.5*2 | 18.5*2 |

| Rorary knife Motor Power(kw) | 5.5 | 5.5 | 7.5 | 7.5 |

| Rewind motor(kw) | 15*2 | 15*2 | 15*2 | 18.5*2 |

| Total power(kw) | 70kw | 78kw | 78kw | 85kw |

| Power supply | 380V 50HZ 3phases(other voltage can be customized) | |||

| Air supply | 0.6-0.8 Mpa, 0.8m3/Min | |||

| Net weight(kg) | 7000 | 8000 | 9000 | 11000 |

| Overall Dimension(mm) | 6000*4300*4000 | 6000*4600*4000 | 6000*4800*4000 | 6000*5000*4000 |

Features:

1. Three individual five motors with ABB inverters synchronous control provides accurate web tension which is calculated by PLC.

2. Siemens PLC control system with touch screen brings much convenience for the operator, it has multi-functions, like meter reached auto stop, tension auto control, and so on.

3. Heavy-duty shaftless unwind with hydraulic auto loading for heavy jumbo rolls and web guiding system to detect the web position.

4. Special rewinding structure, two big drum rollers help to rewind at high speed stably.

5. Automatic hydraulic rolls unloading structure for rewinding shaft is convenient to unload the heavy rolls.

6. Fully automatic pneumatic knife adjustment, you just need to set the knife distance on a touch screen.

Standard Configurations:

Unwinding section: heavy-duty motor drive unwind

- Floating type shaft-less unwind stand, 3” and 6” step chuck.

- Hydraulic lifter for heavy jumbo roll, Max diameter 1800mm and Max weight 3600kg.

- The Left and right arm is controlled by hydraulic and can be moved separately.

- The web adjustment roller ensures the web tension balance from left to right.

- Tension is calculated by PLC and controlled by two sets of motors automatically.

- Web-guiding system: ultrasonic sensor(Pausource) to detect the web position.

- Constant closed-loop tension control system: the tension is sensed by the load cell sensor and compared to the set tension.

Slitting section: motor drive

- Knife rollers are driven by a motor

- Pneumatic automatic rotary knife: full automatic, just need to set distance on touch screen, the knife can be moved to set position automatically.

- Trim disposal: 3kw trim suction fan.

Rewinding section

- Single rewind shaft surface winding structure, 1 pc 3” air shaft, the Max. rewind diameter 1500mm.

- Two big drum rollers which are controlled by motors with gear reducers guarantee the stablity when high speed rewinding(600-800m/min)

- Hydraulic lay-on big metal roller moving on guiding rails guarantees full contact between lay-on roller and slit roll, the lay-on pressure can be adjusted.

- Hydraulic unloading system with pneumatic pusher helps heavy rolls unloading as well as efficiency during slit roll exchange.

- Pneumatic lock for rewind shaft.

- Banana roller to spread the web.

- Protective cover for rewinder

PLC and touch screen

- Colorful 10” touch-screen and PLC (Siemens).

- Chinese, English and Russian language(optional) on touch screen

- Automatic tension& diameter calculate and control: Set taper and initial tension on touch screen for your materials, PLC will detect current tension and current diameter automatically and accurately.

- Meter reached auto alarm and stop function.

- Unwind Set diameter reached auto alarm and stop function.

- One button auto speed up function: Press one button, machine will speed up to your set speed smoothly and automatically.

- Rewind shaft forward and backward function.

- Problem diagnosis function on touch screen, if any problems occur, you can check I/O page to find it.

The quotation will be sent soon!

Leave a Message to get quotation

Fill in the form below to get a quotation in 24 hours

Pls contact us for detail information!

Get In Touch

Contact person: Tom Miao

Phone/Whatsapp/Wechat: +86-13587585227

Email1: tom@slittermachinery.com

Email2: tom@hochint.com