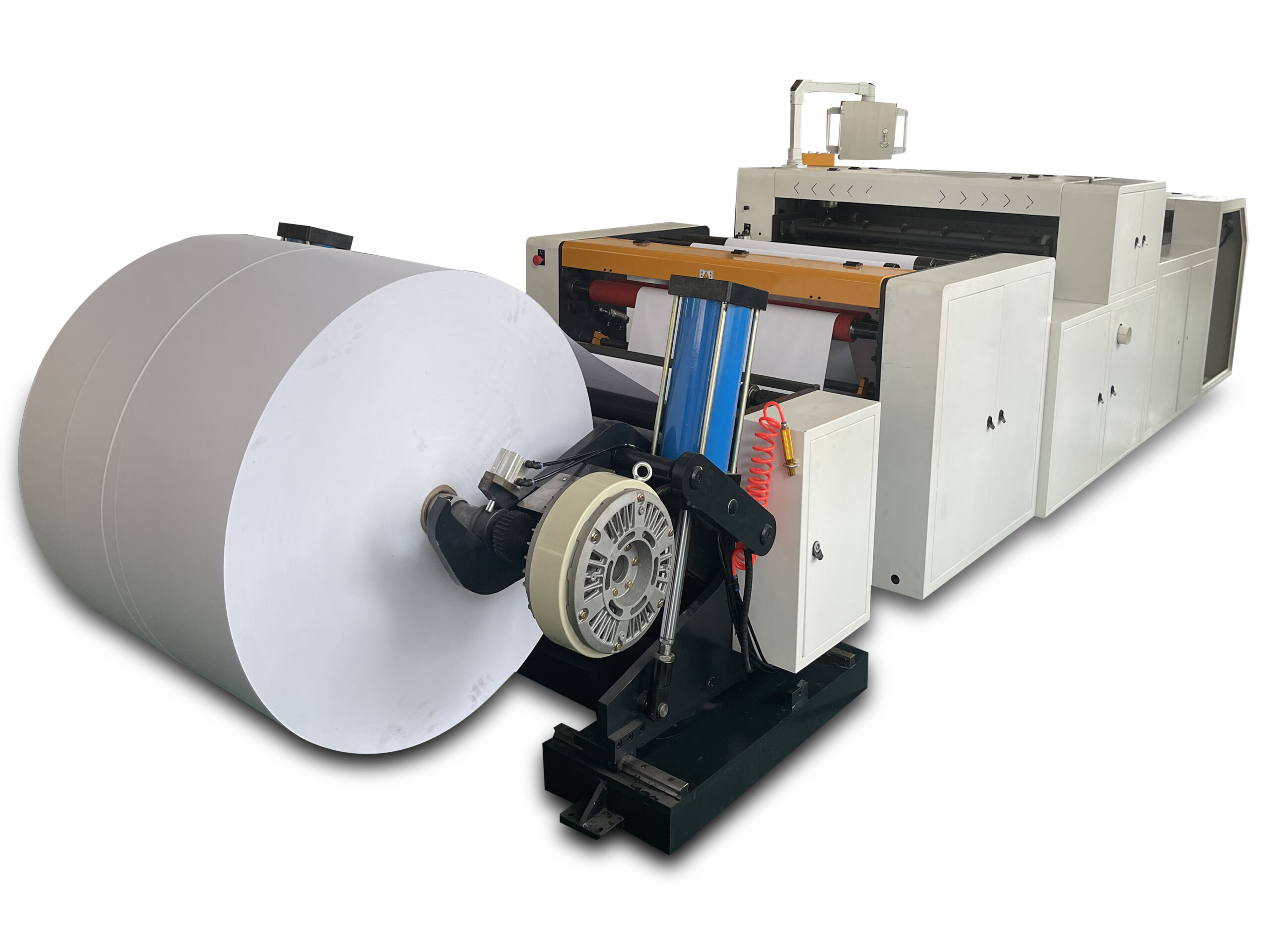

HKS(c) roll to sheet cutter(A4/A3 size)

- Suitable materials:70-200g paper to make A4/A3 size sheets

- Web width: 800-1100-1400mm

- Shafted unwind, Max. diameter 1400mm

- Stack type: side conveyor.

- PLC and HMI design

This machine is specially designed for cutting A4 or A3 size paper. Equipped with a conveyor stacker, you can get a stack of A4 or A3 paper directly.

√ one-year guarantee √ 24 hours technology support √ engineer available for installation

| Model | HKS(C)-800 | HKS(C)-1100 | HKS(C)-1400 | HKS(C)-1600 | |

| Max. web width(mm) | 800 | 1100 | 1400 | 1600 | |

| Max. unwind diameter(mm) | Φ1400 | ||||

| Unwinding stand | Lift-out airshaft & pneumatic auto loading type | ||||

| Unwinding tension control | Magnetic powder brake with PLC control | ||||

| Inner core diameter(mm) | 76mm(3”) | ||||

| Web guiding system | Ultrasonic sensor | ||||

| Cutting sheet size(mm) | A3(297mm×420mm) or A4(210mm×297mm) | ||||

| Precision of cross cutting | ±0.2 | ||||

| Stacker type | Conveyor+side conveyor | ||||

| Max. pile stack height(mm) | 80 | ||||

| Max. speed(times/min) | 120-150 times/min (Based on the cutting length and materials) | 80-120 times/min (Based on the cutting length and materials) | |||

| Cutting Thickness | For paper:70-250g | ||||

| Unwind traction motor(kw) | 1.5 | 1.5 | 1.5 | 1.5 | |

| Servo motor(kw) | 3 | 3 | 4.4 | 4.4 | |

| Knife motor power(kw) | 1.5 | 1.5 | 2.2 | 2.2 | |

| Conveyor motors(kw) | 1.5 | 1.5 | 1.5 | 1.5 | |

| Total power(kw) | 9 | 10 | 15 | 17 | |

| Power supply | 380V 50HZ 3phases(other voltage can be customized) | ||||

| Air supply | 0.6-0.8 Mpa, 0.8m3/Min | ||||

| Weight(kg) | 2000 | 2500 | 3000 | 3500 | |

| Overall Dimension(mm) | 6000*3300*1900 | 6000*3600*1900 | 6000*3900*1900 | 6000*4100*1900 | |

Features:

| 1. PLC with touch screen control with functions of auto counting, auto length setting, auto machine alarm and auto tension control system, etc.

2. Servo motor with driver to control the cutting length of web with high precision. 3. Shafted unwind with pneumatic auto loading for heavy jumbo rolls and web guiding system to detect the web position. 4. Pneumatic dancer roller unit for auto speed varied and assures that the stable web feeding under high speed running. 5. Heavy-duty casting knife holder and high-quality steel cutting knife ensure clean cutting quality and a long usage life. 6. Equipped with rotary shear slitting knife and waste blowing fan to slit the web into any desired width. 7. Equipped with conveyor stacker, you can run machine nonstop and get ready sheets batch by batch. |

Standard configuration:

| > Unwind section: shafted unwind |

| 1. Lift-up & floating type unwinding stand with 3” airshaft., the Max.unwind diameter 1400mm.

2. Pneumatic lock for unwind air shaft. 3. Tension is calculated by PLC and controlled by magnetic brake automatically. 4. Web adjustment roller ensures the web tension balance from left to right. 5. Web-guiding system: ultrasonic sensor to detect the web position. |

| > Traction and dancing roller unit |

| 1. The rubber traction roller is driven by motor with gear reducer.

2. Pneumatic nip rubber roller, the pressure of nip can be adjusted. 3. Pneumatic dancer roller unit for auto speed varied and assures that the stable web feeding under high speed running. 4. Encoder for dancer roller to detect the position accurately which is displayed on touch screen, and the traction speed can be adjusted based on the position of dancer roller. |

| > Feeding and cutting section |

| 1. Servo motor with driver to control the cutting length of web with high precision.

2. Pneumatic nip rubber roller, the pressure of nip can be adjusted. 3. Heavy-duty casting knife holder, bottom knife is fixed and upper blade is movable. 4. High-quality steel cutting knife(2 sets) guarantees clean cutting quality and a long usage life(one set 5-6 years usage life and grind knife every 6-8 months 5. Brake AC motor dirving the cutting knife up-down movement on the Hiwin guiding rails is essential for rapid stopping and holding action. 6. Air blowing system for thin materials. 7. Static eliminator(one side) 8. Pneumatic auxiliary press bar. 9. Rotary shear slitting knives and waste blowing fan for edge trimming. |

| > Conveyor stacker: Main conveyor+side conveyor(can connect to packing machine) |

| 1. Moveable conveyor stacker is easy for the operator to adjust the cutting knife.

2. The conveyors are driven by gear motors can run automatically based on the main machine running. 3. The left/right flick boards and back flick board guarantee the orderly sheets of good quality. 4. With side conveyor, the finished sheets can be deliver in order. |

| > PLC and touch screen |

| 1. Colorful 7” touch-screen(Weinview,Taiwan) and PLC (Panasonic, Japan).

2. Chinese, English and Russian language(optional) on touch screen 3. Cutting length and cutting quantity setting function. 4. Quantity and batch auto counting function. 5. Batch auto conveyor function when reached the set quantity. 6. Automatic tension& diameter calculate and control for unwind. 7. Dancer roller tension display and adjustment. 8. Problem diagnosis function on touch screen, if any problems occur, you can check I/O page to find it. |

Get In Touch

Contact person: Zoe Wu

Phone/Whatsapp/Wechat: +86-13967709531

Email: sales1@slittermachinery.com

If you want to get a quotation, pls fill here

Leave A Comment