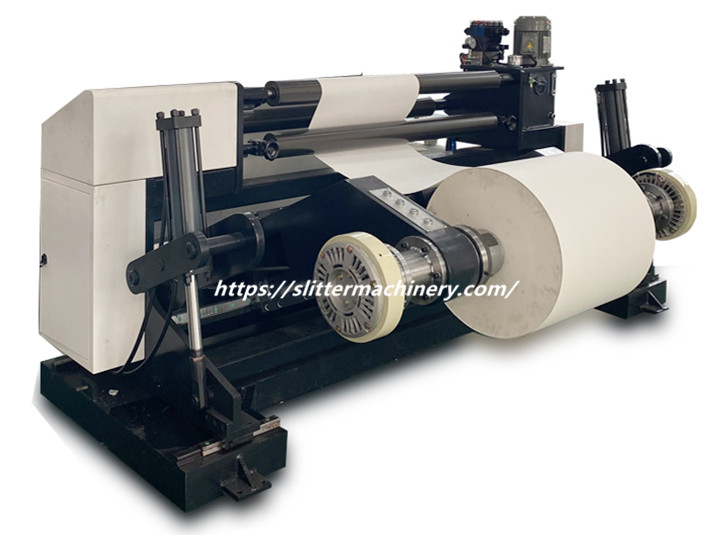

HFQA-W paper slitting rewinding machine

- Suitable materials: 30-450g paper(Main), Sticky label, Various laminates, Film thickness≥30 microns, Nonwoven, etc.

- Web width: 1300-1600-1800-2000mm

- Max. rewind diameter: 1000mm(1200mm can be customized)

- Max. speed ≤400m/min

This machine is suitable for slitting and rewinding large jumbo roll, like various papers, adhesive sticker, films or some laminates into narrow width rolls. We specially designed it with large rewind diameter(1000mm) to fulfill the customers’ requirements who want to get big diameter finished rolls.

√ one-year guarantee √ 24 hours technology support √ engineer available for installation

| Model | HFQA-1300W | HFQA-1600W | HFQA-1800W | HFQA-2000W |

| Max. web width(mm) | 1300 | 1600 | 1800 | 2000 |

| Max. unwind diameter(mm) | Φ1400 | |||

| Unwind stand | Shaft-less auto loading & floating type | |||

| Unwind tension control | Magnetic powder brake with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) and 152mm(6”) step chuck | |||

| Web guiding system | Ultrasonic sensor | |||

| Slitting techniques | Rotary shear knife and Razor blade cutting in air | |||

| Trim disposal | Trim suction fan 2.2kw | |||

| Max. rewinding diameter(mm) | Φ1000(Φ1200 can be customized) | |||

| Rewinding tension control | Two rewinding servo motors with PLC control | |||

| Inner core diameter(mm) | 76mm(3”) | |||

| Min. rewinding web width(mm) | 30 | 40 | 60 | 60 |

| Mechanical speed(m/min) | ≤400 | |||

| Cutting thickness | For paper:30-300g, For film: 30-300μm (according to the materials) | |||

| Cutting accuracy(mm) | ±0.15 | |||

| Main Motor Power(kw) | 7.5 | 7.5 | 11 | 11 |

| Rewind motor(kw) | 7.5*2 | 7.5*2 | 11*2 | 11*2 |

| Total power(kw) | 27 | 27 | 37 | 37 |

| Power supply | 380V 50HZ 3phases(other voltage can be customized) | |||

| Air supply | 0.6-0.8 Mpa, 0.8m3/Min | |||

| Net weight(kg) | 4500 | 5200 | 5800 | 6000 |

| Overall Dimension(mm) | 3700*3100*2100 | 3700*3400*2100 | 3700*3600*2100 | 3700*3800*2100 |

Features:

1. Three individual servo motors’ synchronous control provides accurate web tension which is calculated by PLC.

2. Siemens PLC control system with touch screen brings much convenience for the operator, it has multi-functions, like meter reached auto stop, tension auto control, and so on.

3. Shaftless unwind with hydraulic auto loading for heavy jumbo rolls and web guiding system to detect the web position.

4. Automatic rolls unloading structure for rewinding shafts: mechanical arm moving on the linear guide rail to unload the shaft.

5. Be equipped with rotary shear slitting knives and a high-power trim edge suction fan.

Standard configuration:

Unwinding system

- shaft-less unwinder, 3” and 6” use in common.

- Hydraulic lifter for heavy jumbo roll, Max diameter 1400mm and Max weight 2t.

- The left and right arms are controlled by hydraulic and can be moved separately.

- Tension control by magnetic powder brake

- Web-guiding system: an ultrasonic sensor to detect the web position

Transmission and driven system

- Main servo motor with frequency converter.

- Synchronous belt transmission.

- Pneumatic nip rubber roller.

Slitting section

- Circular knives 10 pcs

- Trim disposal: 3kw trim suction fan

Rewinding section

- Servo motor 2pcs for rewinding.

- Auto unloading system(Click here to see video): mechanical arm moving on the linear guide rail to unload the shaft with finished rolls

- 3-inch air shafts*2, the Max. Diameter is Φ1000

- Pneumatic lay-on roller guarantees full contact between lay-on roller and slit roll

Electric section

- LCD colorful touch-screen and PLC (Siemens).

- Unwinding tension control and rewinding tension adjustment.

- Speed adjustment function.

Get In Touch

Contact person: Tom Miao

Phone/Whatsapp/Wechat: +86-13587585227

Email: tom@slittermachinery.com

If you want to get a quotation, pls fill here

HFQA for Paper and laminates

Testing video of various papers, Our HFQA can do!

Kraft paper 230 gsm

specialty paper

laminated paper

Silicon paper 90 gsm

Variant

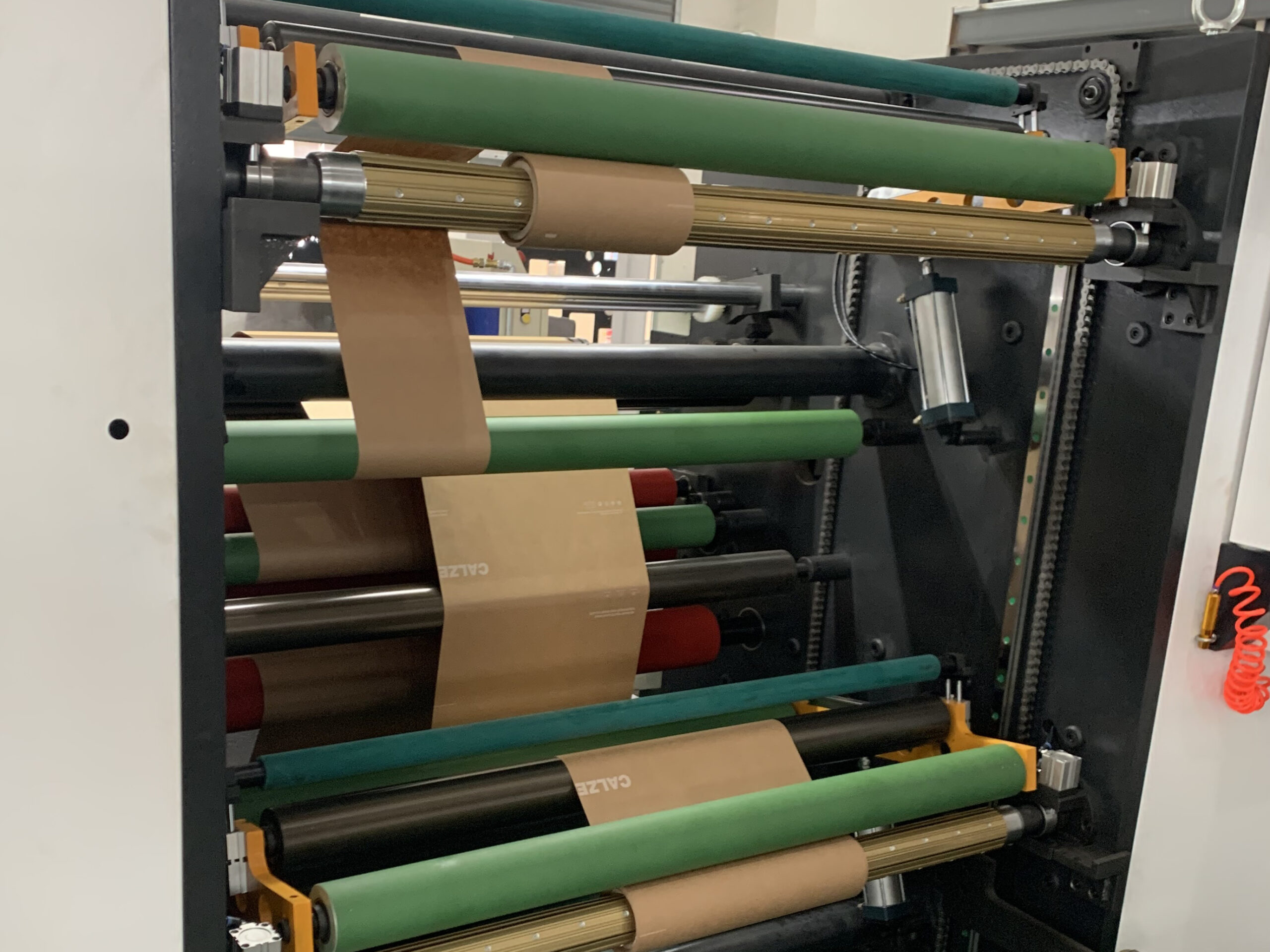

HFQA-1300W-1600W slitter rewinder with glue coated device

This machine is specially designed based on the customer’s requirements. Adding an independent glue coating unit, the paper roll is unwound and pulled through the glue coating unit and slitting shear knives, finally is rewound to duplex airshaft. The client can get the narrow glue-coated paper rolls directly at one time. All idle rollers in this machine are Teflon coated to prevent the sticky side of the web.

Glue Coating Unit

Teflon Coated Roller

Leave A Comment